2PC Ball Valve 1000 WOG Mounting Pad

1000PSI / PN16~PN63

1/4″~4″ (8mm~100mm)

WCB, S.S.304, S.S.316

2PC Ball Valve 1000WOG Mounting Pad Descriptions

2pc ball valve 1000WOG mounting pad ISO 5211 is normally used with pneumatic actuator and electric actuator in the automatic control system. 2pc ball valve 1000WOG direct mounting pad can be divided into 2pc ball valve stainless steel 304(CF8), 316(CF8M) and 2pc ball valve carbon steel (WCB) according to valve materials with pressure of 1000psi. The 2pc ball valve 1000WOG mounting pad lever can be with locking device as optional. Flowspec Luokai can manufacture and supply the 2pc ball valve 1000WOG mounting pad in accordance with ASME B16.34 with sizes of 1/4″~4″ (DN8~DN100mm). Just feel free to contact us now to get best prices. 30 years of experience. High quality. Big stock. Fast delivery.

1. FEATURES

- Full port

- Fully opening or closing

- Blow-out proof stem, reliable sealing

- Two pieces structure, easy operation and maintenance

- PED97/23/EC (CE0035) approved

- Investment casting approved to AD2000-WO certificate

3. STANDARDS

- Design & manufacturing: ASME B16.34

- Female threaded x female threaded: G, NPT, PT, Rp, Rc (ASME B1.20.1, BS21/2799, DIN2999/259, ISO228-1, JIS B 0203, ISO7/1)

- Inspection & testing: API598, EN12266, DIN3230/3

2. TECHNICAL SPECIFICATIONS

- 1000PSI / PN16~PN63

- Size: 1/4″~4″ (DN8~DN100mm)

- Materials: steel (WCB), stainless steel 304(CF8), stainless steel 316(CF8M)

- Applicable medium: water, oil, gas, corrosive liquids

- Applicable temperature: -29℃~+120℃ (higher temperature is available upon request)

4. APPLICATIONS

- Water plant

- Water supply piping system

- HVAC

- Chemical industry

- Oil & gas

- Water treatment plant

- Food & beverage

- Textile

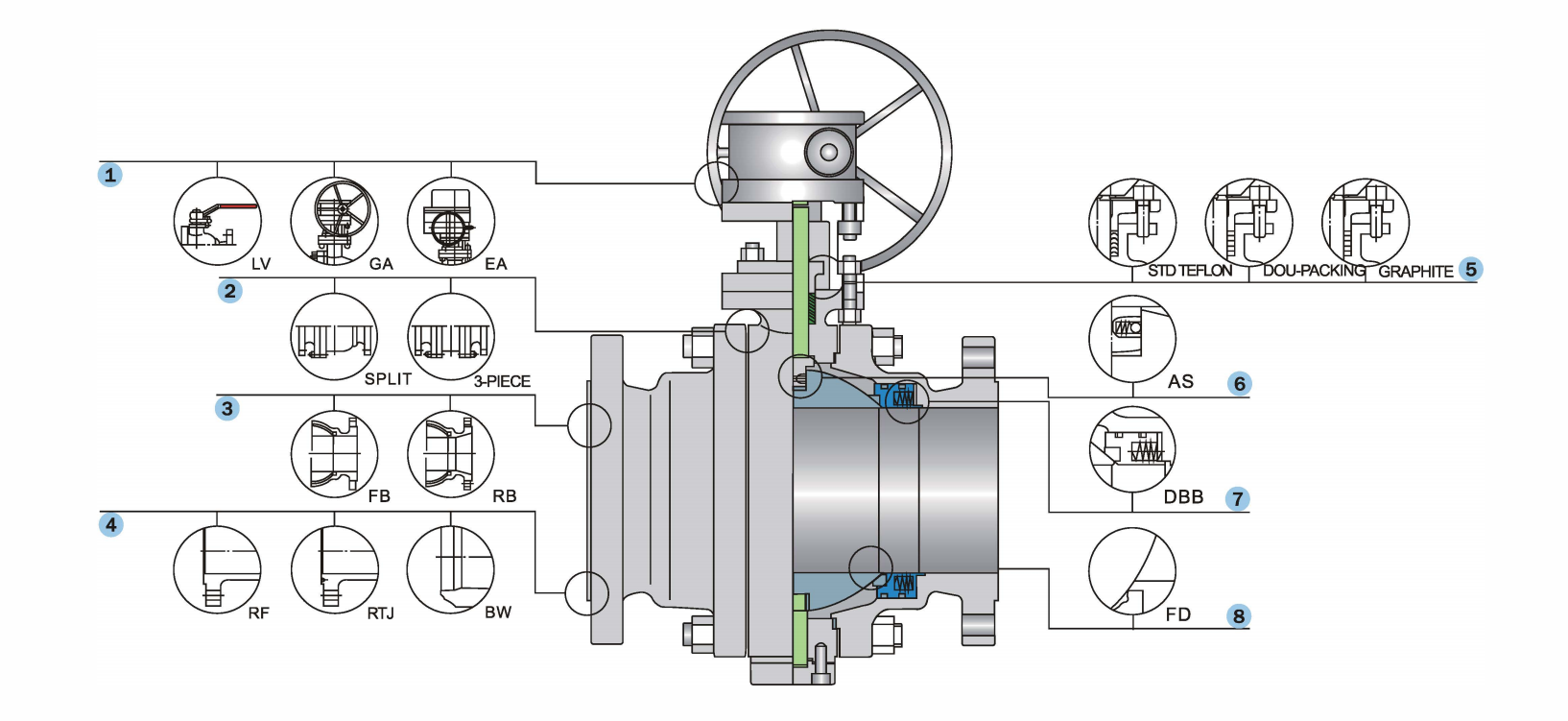

1 Operating

Extended le ver for easy

operation. Also available with

gearing, motor actuators,

pneumatic or hydraulic

actuators for more difficult

services.

2 BODY & BONNET

Split or 3-piece, split

body & bonnet for 12″& Small.

Disassembles easily for repair

or replacement of internal

components.

3 BORE

Full Bore or Reduced Bore.

Full-bore design provides

exceptional flow control

4 End Connections

A choice of Flanged,

RTJ flanged or Buttwelding

end for piping flexibility

5 Packing

STD Packing Multiple V-TEFLON

packing, combined with live

loading, maintains packing

compression under high-cycle

and severe service applications.

Graphite packing use

situat ior for high-temperature.

6 AS

Anti Static. A metallic contact is always

granted between ball and stem/ body

to discharge eventual static s build-op

during service.

7 DDB

Double Block& Bleed, The body cavity

is isolated when the ball is in either fully

closed of fully opened position. The

medium entrapped in it can easily be bled

to avoid over pressure.

8 FD

Fire Durable. Designed to API 607 or BS

6755 to grant their operation suitability in

case of fire. Secondary metal-to-metal

seal acts as backup if primary seal is

destroyed by fire. Valves ordered for

compliance with API 607 will be provided

with graphite packing and gaskets.

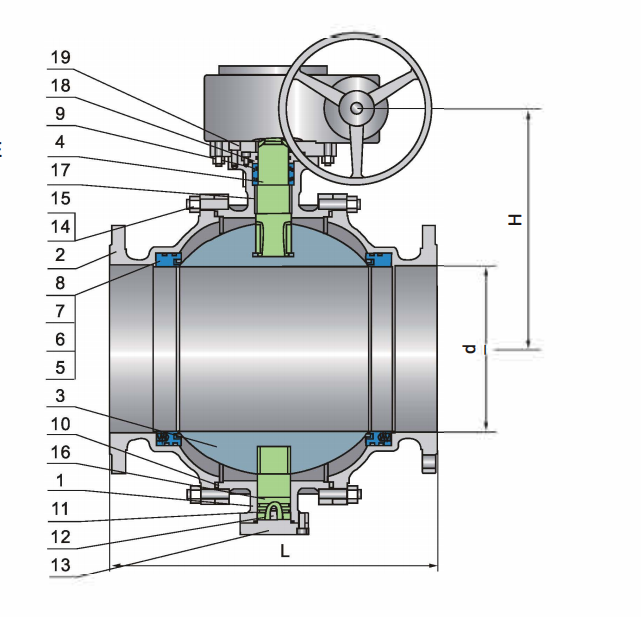

| No | Part Name | ASTM Material | ||

|---|---|---|---|---|

| Carbon Steel | 18Cr-9Ni-2Mo | Carbon Steel | ||

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Bonnet | A216-WCB | A351-CF8M | A352-LCB |

| 3 | Ball | A182-F304¹⁾ | A182-F316 | A182-F304¹⁾ |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat | A105+ENP | A182-F316 | A350-LF2+ENP |

| 6 | Seat Insert | Glass Filled PTFE | ||

| 7 | Seat Spring | A313-304 | Inconel X-750 | A313-304 |

| 8 | Seat O-Ring | NBR | Viton | Viton |

| 9 | Stem O-Ring | NBR | Viton | Viton |

| 10 | Bonnet Gasket | Graphite+304²⁾ | Graphite+316²⁾ | Graphite+304²⁾ |

| 11 | Bonnet O-Ring | NBR | Viton | Viton |

| 12 | Antistatic Spring | A313-304 | A313-316 | A313-304 |

| 13 | Grounding Plunger | A216-WCB | A182-F316 | A182-F304 |

| 14 | Bonnet Stud | A193-B7 | A193-B8 | A320-L7 |

| 15 | Bonnet Stud Nut | A194-2H | A194-8 | A194-4 |

| 16 | Trunnion | A276-304 | A276-316 | A276-304 |

| 17 | Trunnion Bearing | 304+PTFE | 316+PTFE | 304+PTFE |

| 18 | Gland Flange | A216-WCB | A351-CF8M | A352-LCB |

| 19 | Gland Bolt | A193-B7 | A193-B8 | A193-B7 |

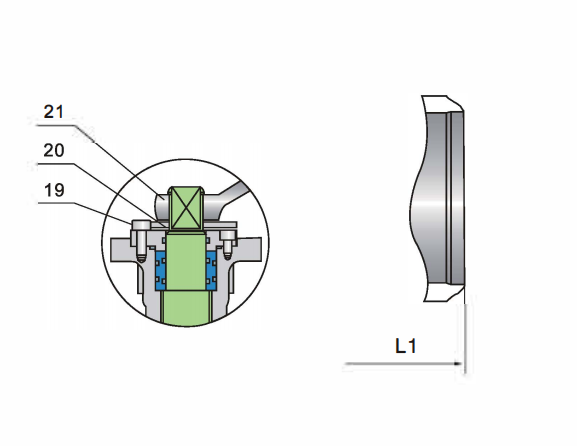

| 20 | Stop Plate | Carbon Steel | Carbon Steel+Zn | Carbon Steel |

| 21 | Handle | Carbon Steel | ||

| Note:1). A105+ENP optional 2). Spiral wound construction. |

||||

| NPS DN |

1/2 15 |

3/4 20 |

1 25 |

1½40 | 2 50 |

2½40 | 3 80 |

4 100 |

6 150 |

8 200 |

10 250 |

12 300 |

in mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANSI Class 150Lb | |||||||||||||

| L (RF) |

4.25 108 |

4.62 117 |

5.00 127 |

6.50 165 |

7.00 178 |

7.50 190 |

8.00 203 |

9.00 229 |

15.50 394 |

18.00 457 |

21.00 533 |

24.00 610 |

in mm |

| L1 (BW) |

5.50 140 |

6.00 152 |

6.50 165 |

7.50 190 |

8.50 216 |

9.50 241 |

11.12 283 |

12.00 305 |

18.00 457 |

20.50 521 |

22.00 559 |

25.00 635 |

in mm |

| H | 2.12 55 |

2.12 55 |

2.75 70 |

3.50 90 |

4.12 105 |

6.12 155 |

7.25 185 |

8.00 205 |

10.00 255 |

11.00 280 |

13.50 345 |

16.50 420 |

in mm |

| (d) | 13 | 19 | 25 | 38 | 49 | 62 | 74 | 100 | 150 | 201 | 252 | 303 | mm |

| W | 5 130 |

5 130 |

6 160 |

8 200 |

14 350 |

16 400 |

20 500 |

20 500 |

24 600 |

32 800 |

32 800 |

32 800 |

in mm |

| WT (kg) |

2.3 1.8 |

3 2.8 |

4.5 3.7 |

7 6.2 |

9.5 8.5 |

15 14 |

19 21 |

33 35 |

93 98 |

160 170 |

200 225 |

280 295 |

RF BW |