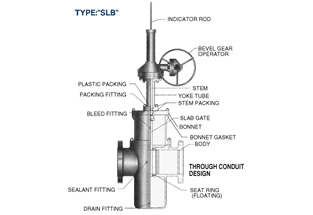

ANSI Slab Gate Valve Product Descriptions

ANSI slab gate valve is also called cast flat gate valve, which is designed and manufactured in accordance with ASME B16.34 / API6D.

The seat ring uses the floating seat ring structure with O-seal ring sealed and pre tightening force applied to have inlet and outlet dual-way sealed; and the open-close moment with this structure is 1/2 that of the common valves only, able to lightly open and close valves.

The seat ring uses the sealing face inlaid with PTFE, so has dual seals of PTFE to metal and metal to metal, the PTFE sealing face also acts as removing the dirt on the wedge disc.

For the slab gate valve with metal to metal seal, there is grease injector outside of it, grease gets into the sealing face through the injector and the seat ring to have the valve up to null leak.

The wedge disc of the valve with flow guide hole is always fitted with the sealing face whether in full open or full close status to have the sealing face protected without being directly eroded by the medium so as to extend the duration.

When fully opened, the valve’s channel is smooth and linear with an extremely small flow resisting coefficient and no pressure loss, and the pipeline can be cleaned with hair-ball through it.

This valve uses the packing structure with the ability of self-seat, needs no contact adjustment, features very light open and close and a reliable seal. An assisting sealing grease injection structure is set in the packing to have the sealing performance absolutely reliable and get a true null leak, setting the problem for the packing place of universal valves to be easiest leak outwards.

Automatic removal of the high pressure in the internal cavity when the valve is about to close, so as to ensure safety.

An indication rod or viewing window is set with the valve to show the open-close condition. Flowspec Luokai manufactures the ANSI slab gate valve in accordance with ASME B16.34 / API6D. Contact us today. Get the better prices. 30 years of experience. Great after-sales service.

1. FEATURES

- Full bore design

- OS&Y, outside screw and yoke

- BB, bolted bonnet

- Parallel single or double disc type

- K type or V type open double wedge disc

- Flexible wedge (2″ Solid) , fully guided

- Choice of solid or split wedge

- Renewable seat rings is available

- Forged T-head stem

- Rising stem and non-rising handwhweel

- Conduction current or non-conduction current patterm

- Available with gear operator

3. STANDARDS

- Design & manufacturing: ASME B16.34 / API6D

- Steel gate valve: ISO14313

- Face to face: ANSI B16.10

- Flanged ends: ANSI B16.5/B16.47

- Butt-welding ends: ASME B16.25, MSS SP44

- Inspection & testing: API598/API6D

2. TECHNICAL SPECIFICATIONS

- 150LB~2500LB

- Size: 1″~40″ (DN25~1000mm)

- Materials: steel A216 WCB, stainless steel 304 A351 CF8, stainless steel 316 CF8M, CF3, CF3M

- Applicable medium: water, oil, gas, corrosive

- Applicable temperature: -29℃~+121℃ (higher temperature is available upon request)

4. APPLICATIONS

- Mining, steel industry

- Coal, slurry industry

- Paper making industry

- Power plant

- Oil, chemical industry

- Fertilizer, pharmaceutical industry

- Waste water, sludge, sewage treatment industry