3 Steps To Perfectly Train Your Valve And Control Engineers

secureluokai

secureluokai

May 3, 2017

May 3, 2017

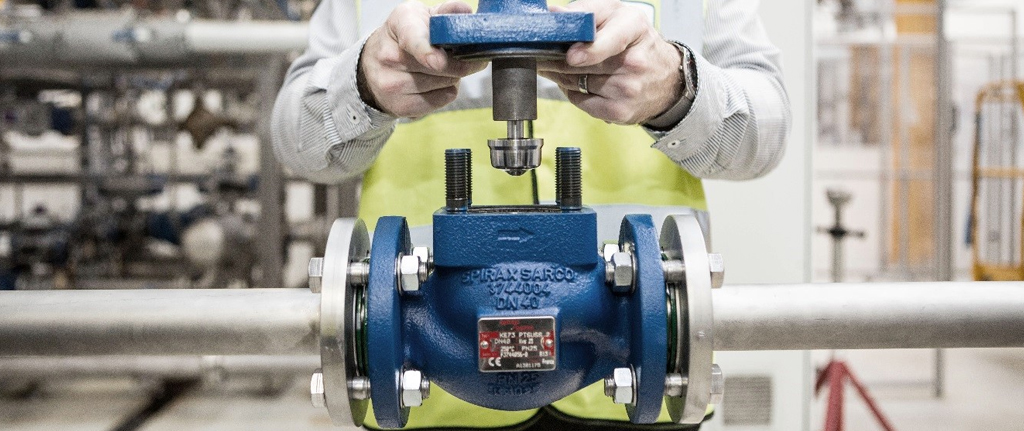

Needless to say, valve and control engineers form a vital lifeline of your manufacturing plant. From controlling the processes, to up-keeping and maintaining them, valve and control engineers have a lot to handle. However, as the industry continues to grow, there is an increased need to hire a skilled and suitably trained workforce.

While hiring new engineers is important, it is essential that you train your existing and new recruits thoroughly and make them understand the various nuances of the industry. This would not only boost the plant’s productivity but would also eliminate the possibility of system breakdown and workplace casualties.

Here are a few quick tips that would ensure that your workforce is properly trained and skilled. Check out!

- Know the basics

Begin the process by providing proper knowledge on valves, uses, types and the likes to your valve and control engineers. Further, put in some time to instruct them on the recent maintenance and mending systems, as well as the techniques and the standard protocols and processes. More significantly, see to it that they have the entire equipment and resources required whenever the need arises to repair or upkeep valves offsite.

The workforce should have a working knowledge of the different valves they will operate on. The actual usability of all the valves should be known to the field engineers thoroughly. They should have a sound knowledge of how a check valve can stop the reverse flow inside a pipeline, for which they are exclusively designed. Its use as a backup for pump failure and when the pressure of the system surpasses the primary equipment potential should be at every engineer’s fingertips.

Likewise, it is vital for an oil or gas engineer to be aware of the basic valves and their principals and usage. A familiarity with the most common valve in use nowadays, the ball valve is a must. These are quarter-turn circular motion valves and can control a flow. Its utility in air, gases or liquids due to their quick turn on plus off the system and low torque should be known to every engineer.

Like with any equipment, the field engineers should have a foolproof know-how of how to choose the entire process condition before picking up their valve. This includes the item or material, rate of flow or the piping size. If you want to regulate a costly material that you do not want to waste, you probably would not like to depend on a ball valve. Such knowledge of valve service and its applications should be in every engineer’s kitty.

Another common valve in use in various industries is the butterfly valve that is applied to stop, begin or regulate flow. Its proper installation at 6 pipe diameters apart from different line elements and the manner in which it can handle low-pressure drop plus high-pressure return is something that valve and control engineers should know. The uses of gate valves that are basically designed to begin or restrict a flow when straight line fluid flow and minimum flow limitation are needed are required in every training program for engineers.

- Prepare your staff for latest industry technologies

Training your personnel on the latest tools related to the industry and the function of every part of high-tech equipment system and its operation is mandatory. Furthermore, make sure that your engineers have a detailed insight on the early warning signals and problems linked with such technologies. This would help them in controlling the damage and thereby would reduce the system failure.

A right tool enhances the effectiveness of your plant and helps to troubleshoot the fixation problems. Like for example, if you are asked to detect poorly performing control loops, a solution might be to carry out the exercise of viewing each loop and outlining a list of 10 solutions. Chances of it being time-consuming and getting involved in side issues might emerge. But a proper use of control loop supervising tools will provide you with an automatic list depending on key metrics as it monitors the procedures almost every day.

Generally, every control engineer believes that he or she can tune loops promptly by hand. Though engineers can tune loops quickly, but they cannot often properly do it. It is thus highly recommended to promote the use of tools like Process Interaction Mapping for knowing the exact source of control malfunctioning.

- Train workers towards any type of job

Based on your company expansion, it may be necessary for the valve and control engineers to migrate to offsite locations for providing valve services. Give them the cutting edge expertise, so that they have the capability to carry out any work whether in-facility or offsite.

You also probably like to assure that your personnel has access to various resources prior to offsite operations. Eventually, if their work involves managing various valves or processes, possession of proper tools, spare accessories, and documentation, then the engineers do require an in-depth study on the repairing of that specific equipment.

Furthermore, train your workers to focus on main things as it is convenient to lose one’s focus in a plant set up. The real challenge is to remain focused on that part of the work that brings value to the business. It’s in fact very difficult to downsize a person who brings huge value to the company.

Wrapping Up

The bottom line here is to train your engineers to not only boost their productivity, but proper knowledge about various processes would also ensure their safety and avoid any causalities.

What are your views on this? How do you ensure that your valves are functioning properly? For more information about various valves specifically required for your industrial plants / business, Contact Flowspec and we will be happy to answer your questions and give you all the details you need.