2PC ANSI Floating Ball Valve

150LB/300LB/600LB

1/2″~12″ (15~300mm)

WCB, S.S.304, S.S.316

2PC ANSI Floating Ball Valve Product Descriptions

2PC ANSI floating ball valve is the most common flanged type ball valve whose body is two pieces structure with soft seated (PTFE, RPTFE, PPL, VITON) and metal sealed. 2PC ANSI floating ball valve can be divided into 2pc flanged ball valve stainless steel 304(CF8), 316(CF8M) and 2pc flanged ball valve carbon steel (WCB) according to valve materials. Two pieces floating ball valve can be produced especially according to NACE MR01-75 and API607 & API6FA. Flowspec Luokai can manufacture and supply the 2pc ANSI floating ball valve according to the standard of ASME B16.34, API608, API6D with sizes of 1/2″~12″ (DN15~300mm) class 150LB, 300LB and 600LB. Contact us today. Get the better prices. 30 years of experience. Great after-sales service.

1. FEATURES

- Full port

- Fully opening or closing

- Blow-out proof stem, anti-static device

- Two pieces structure, easy operation and maintenance

- PED97/23/EC (CE0035) approved

- Investment casting approved to AD2000-WO certificate

3. STANDARDS

- Design & manufacturing: ASME B16.34, API608, API6D

- Face to face: ANSI B16.10

- Flanged ends: ANSI B16.5 RF

- Inspection & testing: API598

2. TECHNICAL SPECIFICATIONS

- 150LB / 300LB / 600LB

- Size: 1/2″~12″ (DN15~300mm)

- Materials: carbon steel A216 WCB, stainless steel 304(CF8), stainless steel 316(CF8M)

- Applicable medium: water, oil, gas, corrosive liquids

- Applicable temperature: -29℃~+120℃ (higher temperature is available upon request)

4. APPLICATIONS

- Mining, steel industry

- Coal, slurry industry

- Paper making industry

- Power plant

- Oil, chemical industry

- Fertilizer, pharmaceutical industry

- Waste water, sludge, sewage treatment industry

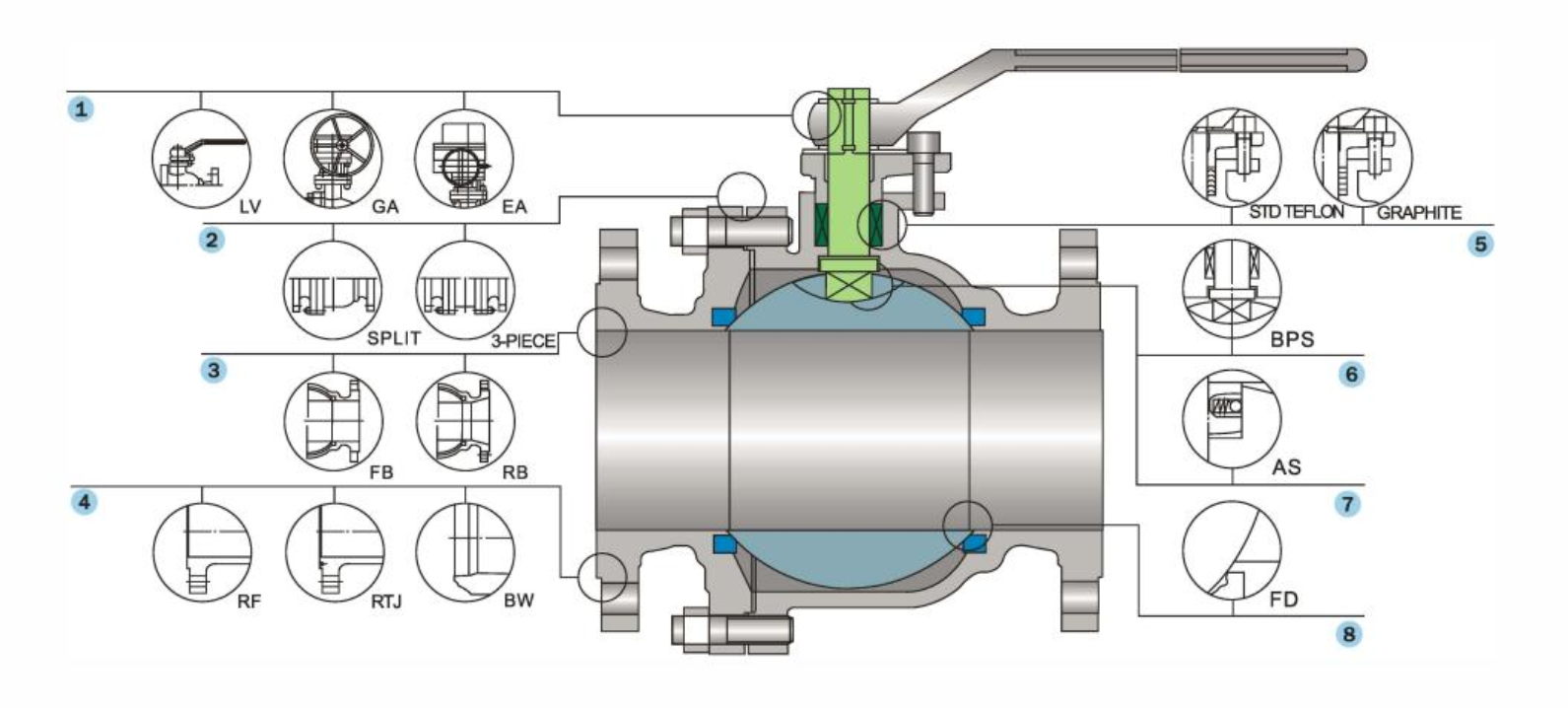

Extended lever for easyoperation. Also available withgearing, motor actuators,pneumatic or hydraulicactuators for more difficultservices.

2 BODY & BONNET

Split or 3-piece, splitbody& bonnet for 12″ & SmallDisassembles easily for repairor replacement of intemalcomponents.

3 BORE

Full Bore or Reduced Bore.Full-bore design providesexceptional flow control

4 End Connections

A choice of Flanged,RTJ flanged or Buttweldingend for pi ping flexibility

5 Packing

STD Packing Multiple V-TEFLONpacking, combined with liveloading, maintains packingcompression under high-cycleand severe service applications.Graphite packing usesituat ior for high-temperature.

6 BPS

Blow-out Proof Stem.A pressure-safestem shoulder design thatprotects against failure underexcess pressure.

7 AS

Anti Static. A metallic contact is alwaysgranted between ball and stem/ bodyto discharge eventual static s build-opduring service.

8 FD

Fire Durable. Designed to API 607 or BS6755 to grant their operation suitability incase of fire. Secondary metal-to-metalseal acts as backup if primary seal isdestroyed by fire. Valves ordered forcompliance with API 607 will be providedwith graphite packing and gaskets.

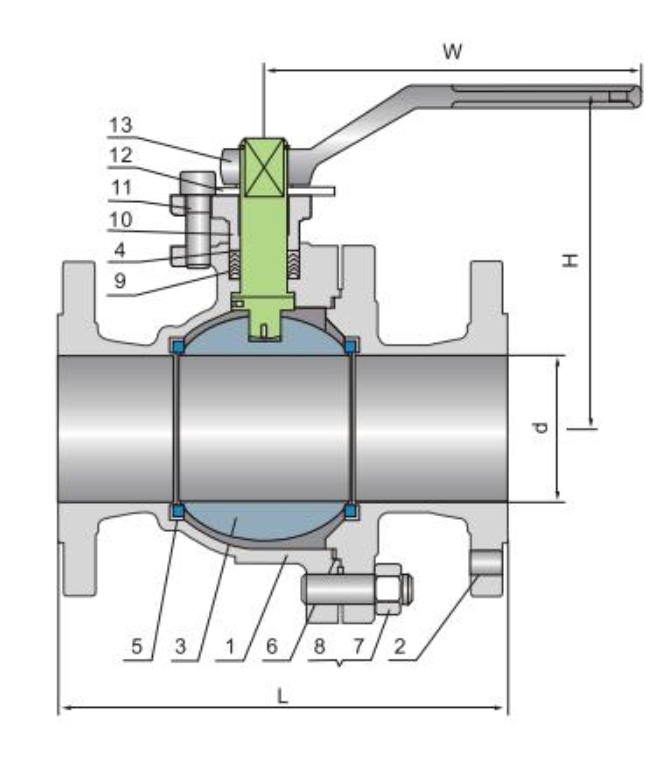

| No | Part Name | ASTM Material | ||

|---|---|---|---|---|

| Carbon Steel | 18Cr-9Ni-2Mo | Carbon Steel | ||

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Bonnet | A216-WCB | A351-CF8M | A352-LCB |

| 3 | Ball | A182-F304¹⁾ | A182-F316 | A182-F304¹⁾ |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat Ring | R. PTFE | ||

| 6 | Bonnet Gasket | Graphite+304²⁾ | PTFE | Graphite+304²⁾ |

| 7 | Bonnet Stud | A193-B7 | A193-B8 | A320-L7 |

| 8 | Bonnet Stud Nut | A194-2H | A194-8 | A194-4 |

| 9 | Packing | PTFE | ||

| 10 | Gland Flange | A216-WCB | A351-CF8M | A352-LCB |

| 11 | Gland Bolt | A193-B7 | A193-B8 | A193-B7 |

| 12 | Stop Plate | Carbon Steel | Carbon Steel+Zn | Carbon Steel |

| 13 | Handle | Carbon Steel | ||

| NPS DN |

1/2 15 |

3/4 20 |

1 25 |

1½40 | 2 50 |

2½40 | 3 80 |

4 100 |

6 150 |

8 200 |

10 250 |

12 300 |

in mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANSI Class 150Lb | |||||||||||||

| L (RF) |

4.25 108 |

4.62 117 |

5.00 127 |

6.50 165 |

7.00 178 |

7.50 190 |

8.00 203 |

9.00 229 |

15.50 394 |

18.00 457 |

21.00 533 |

24.00 610 |

in mm |

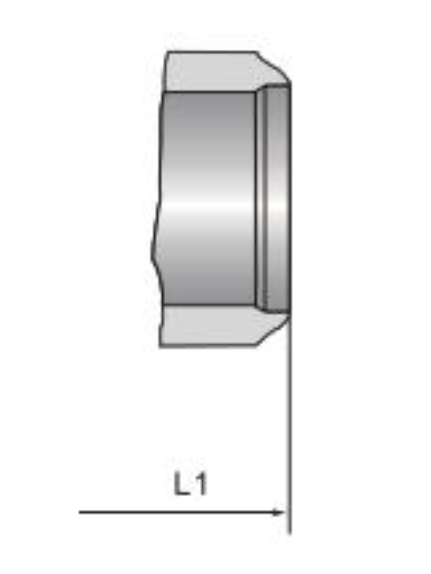

| L1 (BW) |

5.50 140 |

6.00 152 |

6.50 165 |

7.50 190 |

8.50 216 |

9.50 241 |

11.12 283 |

12.00 305 |

18.00 457 |

20.50 521 |

22.00 559 |

25.00 635 |

in mm |

| H | 2.12 55 |

2.12 55 |

2.75 70 |

3.50 90 |

4.12 105 |

6.12 155 |

7.25 185 |

8.00 205 |

10.00 255 |

11.00 280 |

13.50 345 |

16.50 420 |

in mm |

| (d) | 13 | 19 | 25 | 38 | 49 | 62 | 74 | 100 | 150 | 201 | 252 | 303 | mm |

| W | 5 130 |

5 130 |

6 160 |

8 200 |

14 350 |

16 400 |

20 500 |

20 500 |

24 600 |

32 800 |

32 800 |

32 800 |

in mm |

| WT (kg) |

2.3 1.8 |

3 2.8 |

4.5 3.7 |

7 6.2 |

9.5 8.5 |

15 14 |

19 21 |

33 35 |

93 98 |

160 170 |

200 225 |

280 295 |

RF BW |