Double Flanged Eccentric Butterfly Valve

PN10 / PN16 / CL125LB

4″~120″ (100~3000mm)

Cast Iron, Ductile Iron

Double Flanged Eccentric Butterfly Valve Descriptions

Double flanged eccentric butterfly valve is one type of high performance butterfly valve, which is with eccentric action reduces torque and seat contact during operation, extending the valve service life. Its seat can be repaired on site, no needing dis-assembly. The double flanged eccentric butterfly valve is suitable for 90° on-off operation and regulation service. Flowspec Luokai can produce the double flanged butterfly valve according to GB12238, AWWA C504 and EN593. Just feel free to contact us now to get best prices. 30 years of experience. High quality. Big stock. Fast delivery.

1. FEATURES

- Eccentric action reduces torque and seat contact during operation, extending valve service life

- Suitable for 90° on-off operation and regulation service

- The seat can be repaired on site, no needing dis-assembly

- Epoxy coating for corrosion resistance and long service life

- Good sealing capability, no leakage

3. STANDARDS

- Design & manufacturing: GB12238, AWWA C504, EN593

- Face to face: ISO 5752, AWWA C504, GB12221, EN558-1, ANSI B16.10

- Flanged ends: ANSI B16.5 ANSI 125/150; EN1092-2 PN10/PN16, DIN 2501 / BS 4504 / GB 17241.6 PN10/PN16

- Top flange: ISO 5211

- Inspection & testing: API598, GB13927

2. TECHNICAL SPECIFICATIONS

- ANSI 125/150LB, PN1.0/PN1.6MPa, JIS5K/10K

- Size: 4″~120″ (100~3000mm)

- Materials: A126 B (GG25), A536 65-45-12 (GGG40), A216 WCB, S.S.304(CF8), S.S.316(CF8M), B148 C954

- Epoxy coating with thickness ≥250μm

- Applicable medium: water, sewage, sea water, air, food, medicine, oil, corrosive liquids

- Applicable temperature: -20℃~+80℃ (higher temperature is available upon request)

4. APPLICATIONS

- Water works, water projects

- Environment protection

- Public facilities

- Power plant

- Building industry, real estate

- Petroleum, chemical industry

- Steel work, metallurgy

- Water treatment plant

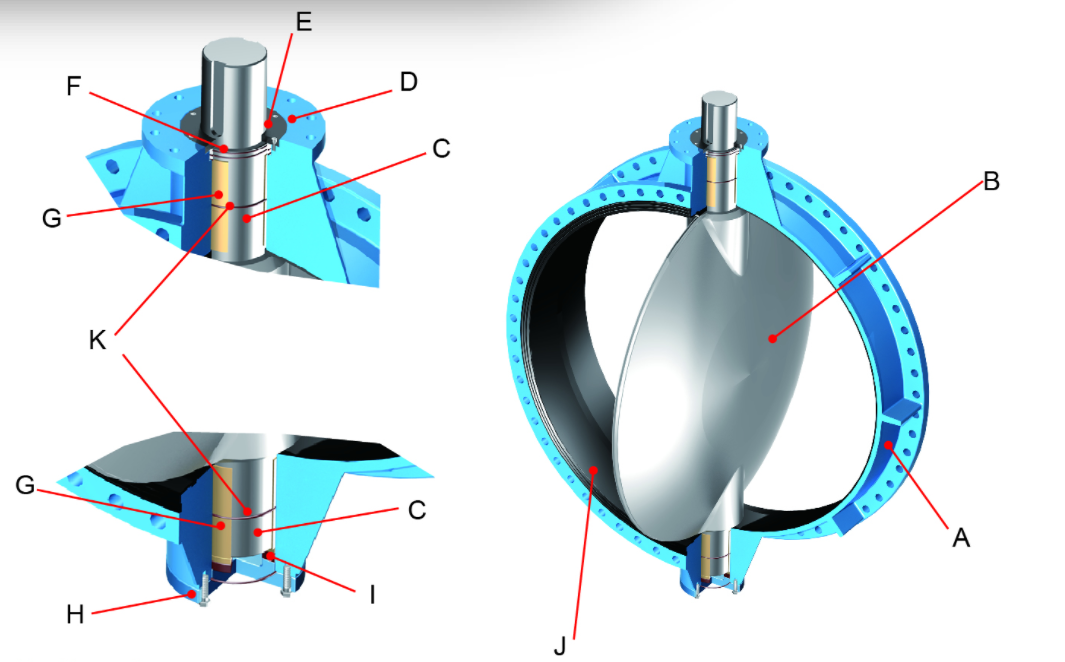

A: Body

Short in structure, light in weight, highstrength, apply to wafer (small diameter) andflange connection.

B: Disc

High strength disc with precise machining,assure bi-direction pressure bearing and noleakage.

C: Shaft

High strength stainless steel shaft can delivertorque effectively.

D: Upper Flange

Available in actuators with various connectionstandards.

E: Packing Gland

Through pressing the packing gland, canprevent stem end from leakage.

F: Sealing Ring

The secondary shaft seal prevents fromimpurities and protects the shaft.

G:Bushing

Made of lubricant and small friction coefficientmaterial, support shaft and reduce rotationtorque.

H: Bottom Cover

Support disc by wearing washer and shaft,prevent falling and assure sealing performance.

I: Wearing Washer

Prevent the shaft end from wearing, reducerotation torque, and assure the disc in rightposition.

J: Seat Sealing Ring

High quality rubber ring, fixed on body, assuresno leakage. No more washers when valveconnects with flange.

K: O-Ring

Applied as secondary seal, prevent shaft endleakage.

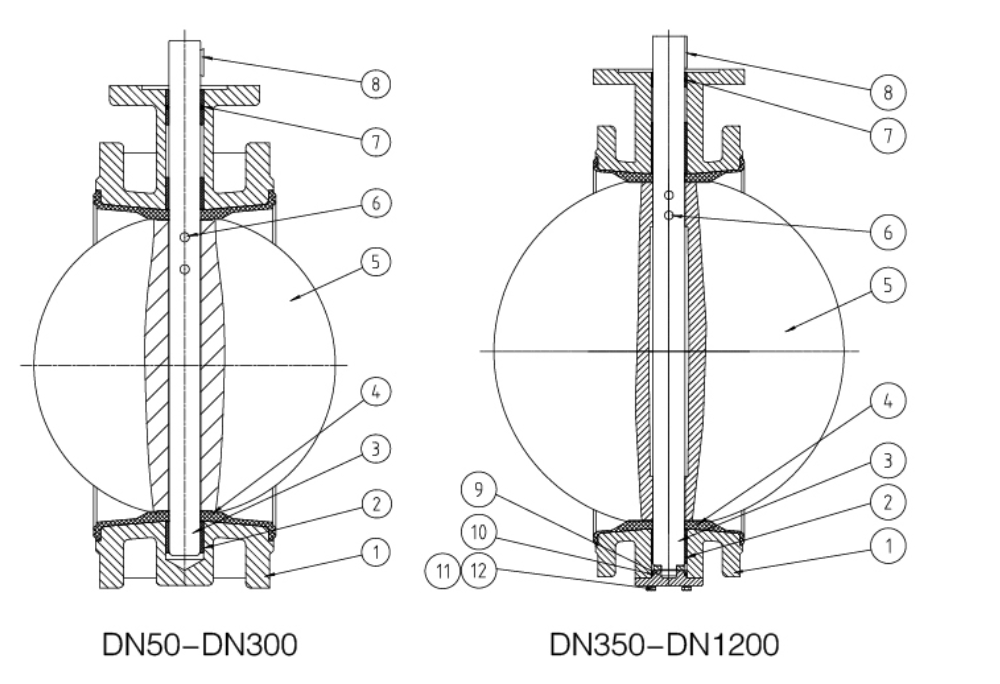

| No. | Part | Material | No. | Part | Material |

|---|---|---|---|---|---|

| 1 | Body | HT200,A126 ClassB QT450-10,A53665-45-12 WCB |

7 | O-Ring | NBR EPDM |

| 2 | Bushing | ZCuZn38Mn2Pb2, Bronze F4 Backing Steel |

8 | Key | 45 1045 |

| 3 | Shaft | 416 420 431 17-4PH | 9 | End Plate | QT450-10 Q235-A Gr33 |

| 4 | Seat | NBR EPDM Viton | 10 | O-Ring | NBR EPDM |

| 5 | Disc | DI ALB CF8 CF8M 1.4529、1.4469 | 11 | Hex. Bolt | Q235-A Gr.33 |

| 6 | Taper Pin | 416 420 431 17-4PH | 12 | Spring Gasket | Spring Steel |

| Note: Materials indicated in above table are for common usage, please give clear declaration in your contract if there is special need. | |||||

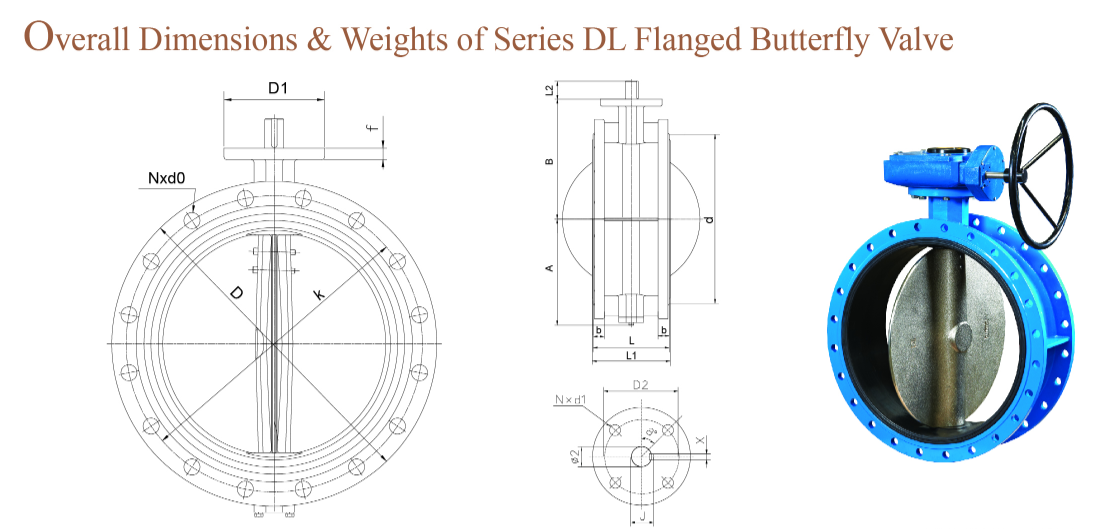

| DN | A | B | b | f | D | K | d | F | N-do | L | L1 | D1 | D2 | N×d1 | a° | J | X | L2 | ∅2 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 83 | 120 | 19 | 3 | 165 | 125 | 99 | 13 | 4-19 | 108 | 111 | 65 | 50 | 4-7 | 45 | 13.8 | 3 | 32 | 12.6 | 7.6 |

| 65 | 93 | 130 | 19 | 3 | 185 | 145 | 118 | 13 | 4-19 | 112 | 115 | 65 | 50 | 4-7 | 45 | 13.8 | 3 | 32 | 12.6 | 9.7 |

| 80 | 100 | 145 | 19 | 3 | 200 | 160 | 132 | 13 | 8-19 | 114 | 117 | 65 | 50 | 4-7 | 45 | 13.8 | 3 | 32 | 12.6 | 10.6 |

| 100 | 114 | 155 | 19 | 3 | 220 | 180 | 156 | 13 | 8-19 | 127 | 130 | 90 | 70 | 4-10 | 45 | 17.77 | 5 | 32 | 15.77 | 13.8 |

| 125 | 125 | 170 | 19 | 3 | 250 | 210 | 184 | 13 | 8-19 | 140 | 143 | 90 | 70 | 4-10 | 45 | 20.92 | 5 | 32 | 18.92 | 18.2 |

| 150 | 143 | 190 | 19 | 3 | 285 | 240 | 211 | 13 | 8-23 | 140 | 143 | 90 | 70 | 4-10 | 45 | 20.92 | 5 | 32 | 18.92 | 21.7 |

| 200 | 170 | 205 | 20 | 3 | 340 | 295 | 266 | 13 | 12-23 | 152 | 155 | 125 | 102 | 4-12 | 45 | 24.1 | 5 | 45 | 22.1 | 31.8 |

| 250 | 198 | 235 | 22 | 3 | 405 | 355 | 319 | 13 | 12-28 | 165 | 168 | 125 | 102 | 4-12 | 45 | 31.45 | 8 | 45 | 28.45 | 44.7 |

| 300 | 223 | 280 | 24.5 | 4 | 460 | 410 | 370 | 20 | 12-28 | 178 | 182 | 125 | 102 | 4-12 | 45 | 34.6 | 8 | 45 | 31.6 | 59 |

| 350 | 270 | 310 | 26.5 | 4 | 520 | 470 | 429 | 20 | 16-28 | 190 | 194 | 150 | 125 | 4-14 | 45 | 36.15 | 10 | 45 | 33.15 | 86 |

| 400 | 300 | 340 | 28 | 4 | 580 | 525 | 480 | 20 | 16-31 | 216 | 221 | 175 | 140 | 4-18 | 45 | 40.95 | 10 | 51 | 37.95 | 119 |

| 450 | 340 | 375 | 30 | 4 | 640 | 585 | 530 | 20 | 20-31 | 222 | 227 | 175 | 140 | 4-18 | 45 | 45.86 | 12 | 51 | 42.86 | 165 |

| 500 | 355 | 430 | 31.5 | 4 | 715 | 650 | 582 | 22 | 20-34 | 229 | 234 | 210 | 165 | 4-22 | 45 | 49.22 | 14 | 57 | 45.72 | 185 |

| 600 | 410 | 500 | 36 | 5 | 840 | 770 | 682 | 22 | 20-37 | 267 | 272 | 300 | 254 | 8-18 | 22.5 | 57.98 | 15 | 70 | 53.98 | 263 |

| 700 | 478 | 560 | 39.5 | 5 | 910 | 840 | 794 | 30 | 24-37 | 292 | 299 | 300 | 254 | 8-18 | 22.5 | 71.35 | 18 | 66 | 63.35 | 361 |

| 800 | 529 | 620 | 43 | 5 | 1025 | 950 | 901 | 30 | 24-41 | 318 | 325 | 350 | 298 | 8-22 | 22.5 | 79 | 20 | 66 | 70 | 484 |

| 900 | 584 | 685 | 46.5 | 5 | 1125 | 1050 | 1001 | 34 | 28-41 | 330 | 337 | 350 | 298 | 8-22 | 22.5 | 90 | 22 | 118 | 80 | 598 |

| 1000 | 657 | 735 | 50 | 5 | 1255 | 1170 | 1112 | 34 | 28-44 | 410 | 417 | 350 | 298 | 8-22 | 22.5 | 100 | 25 | 142 | 90 | 824 |

| 1200 | 799 | 917 | 57 | 5 | 1485 | 1380 | 1328 | 34 | 32-50 | 470 | 478 | 415 | 356 | 8-33 | 22.5 | 117 | 28 | 150 | 105 | 1223 |

| 1400 | 919 | 1040 | 60 | 5 | 1685 | 1590 | 1530 | 40 | 36-50 | 530 | 538 | 415 | 356 | 8-33 | 22.5 | 134 | 32 | 200 | 120 | 2386 |

| 1500 | 965 | 1050 | 62.5 | 5 | 1820 | 1710 | 1630 | 40 | 36-57 | 570 | 580 | 415 | 356 | 8-32 | 22.5 | 156 | 36 | 200 | 140 | 3475 |

| 1600 | 1045 | 1150 | 65 | 5 | 1930 | 1820 | 1700 | 50 | 40-57 | 600 | 610 | 415 | 365 | 8-32 | 22.5 | 156 | 36 | 200 | 140 | 4055 |

| 1800 | 1280 | 1290 | 70 | 5 | 2130 | 2020 | 1914 | 55 | 44-57 | 670 | 682 | 475 | 406 | 8-40 | 22.5 | 178 | 40 | 280 | 160 | 5570 |

| 2000 | 1350 | 1323 | 75 | 5 | 2345 | 2230 | 2130 | 55 | 48-62 | 760 | 772 | 475 | 406 | 8-40 | 22.5 | 178 | 40 | 280 | 160 | 7240 |