ANSI Swing Check Valve Descriptions

ANSI swing check valve is also called one-way valve or non-return valve, which is used to prevent of mediums back flow in the pipeline. The disc of the check valve is action depending on the mediums itself flow pressure, so the check valve is belonging to automatic valve types. Because the swing check valve is only allowed the mediums to flow in one direction, we should note the arrowhead on the check valve when mount it in horizontal position. Swing check valves are widely used in series of industries, especially in oil & gas filed, power plant, etc. Flowspec Luokai can manufacture the ANSI swing check valve in accordance with ASME b16.34 and BS 1868. Welcome to contact us for detailed information and best quotes if you have any questions or inquiries.

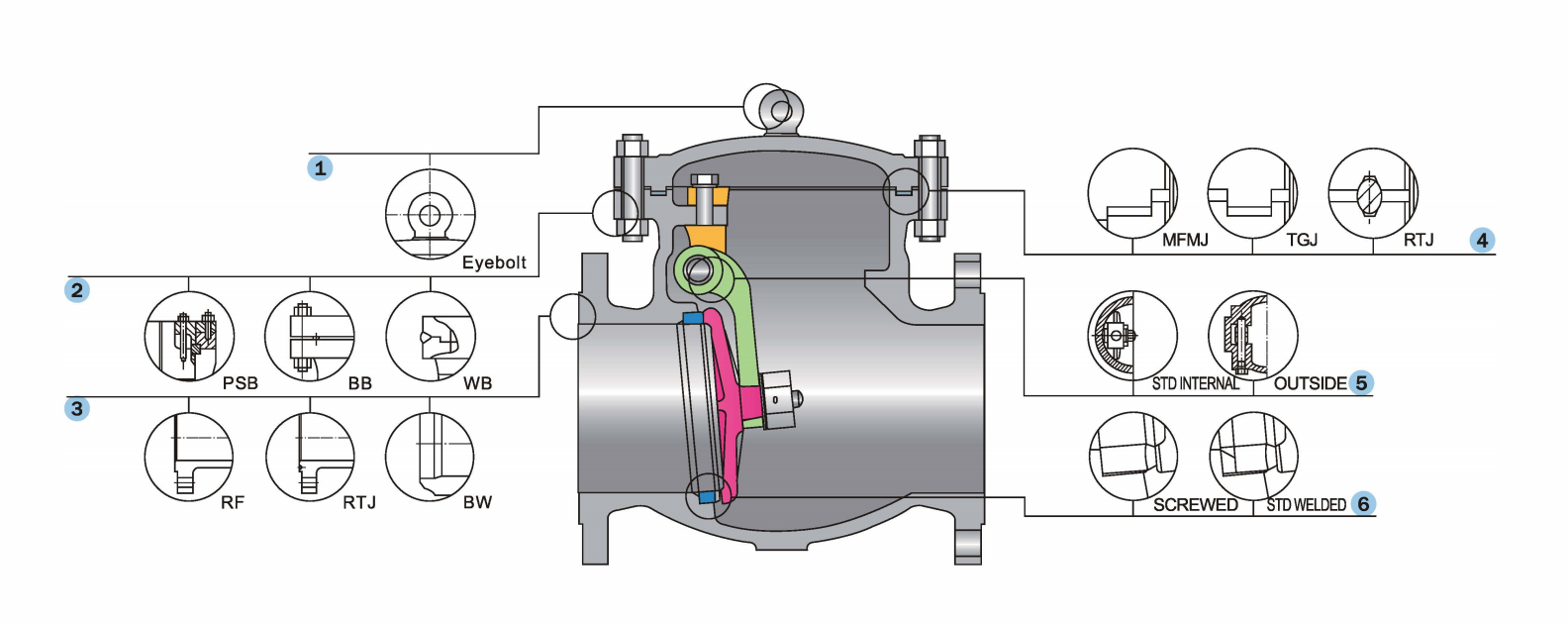

1. FEATURES

- Standard swing type disc

- Standard renewable seat

- BC, bolted cover

- Non-penetrate disc shaft

- Horizontal or vertical service

- Flanged or butt-welding ends

3. STANDARDS

- Design & manufacturing: ASME b16.34 / BS 1868

- Face to face: ASME B16.10

- Flanged ends: ASME B16.5/B16.47

- Inspection & testing: API598

- Special request: NACE MR-01-75

2. TECHNICAL SPECIFICATIONS

- Class: 150LB~2500LB

- Size: 2″ ~ 30″ (DN50~750mm)

- Materials: steel A216 WCB, stainless steel 304 (A351 CF8), stainless steel 316 (A351 CF8M), CrMo alloy steel A217, low temperature A352.

- Applicable medium: water, sea water, oil, gas, corrosive liquids

- Applicable temperature: -29℃~+425℃ (higher temperature is available upon request)

- Special: NACE MR-01-75

4. APPLICATIONS

- Petroleum

- Chemical industry

- Pharmacy

- Chemical fertilizer

- Power plant

- Textile

- Printing & dyeing

- Oil & gas

1 Eyebolt

For 1580Lb-8″,300Lb-8″,600Lb-6″,900Lb/1500Lb/2500Lb-4″&Over.

2 BB

Bolted bonnet. Weldingbonnet and pressureseal bonnet in servicesrequiring frequent cyclingor with high pressure/temperature variations.

3 En d Connections

A choice of Flanged,RTJ flanged or Buttweldingend for piping flexibility.

4 Body-to -Bonnet Joint

A Male and Female joint orTonggue and Groove joint isused 150Lb to 600Lb valves.Ring joint is used in the bodyto bonnet connection in900Lb &higher rated valves.

5 Outside Lever and Weight

All external hinge pin swing checkvalves 12″ and smaller are availablewith an optional outside lever andweight. Internal hinge available withall swing check valves.

6 Seat Rings

Separate heavy duty, fullported rings for easymaintenance. Screwed orwelded connection into body.

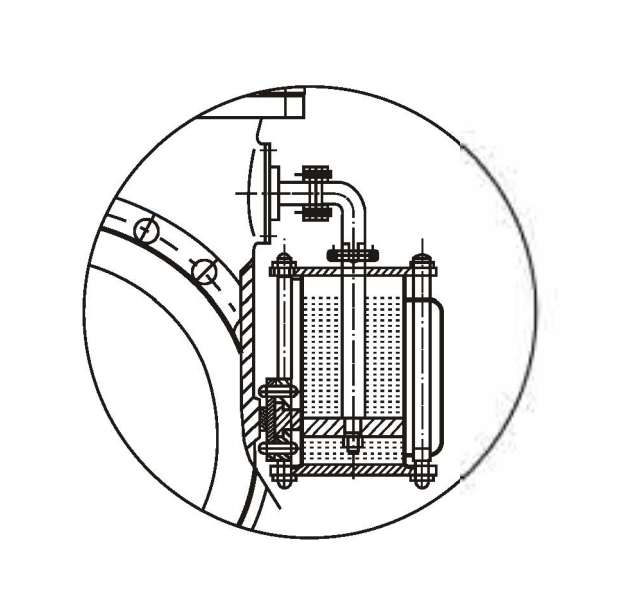

HCU Weighted MechanicalAccumulator

This design can be used toeitherdampen or assisist closingof the check valve discdepending on orientation. By usingthe Hydraulic Control Unit to bufferaction the disc, the valve opens at lower flow rates.

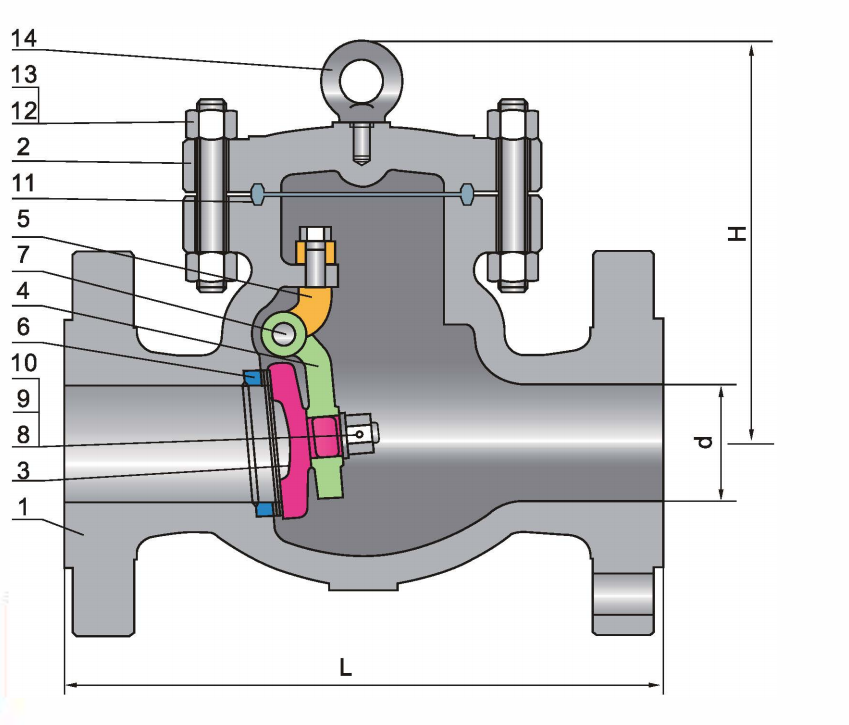

| No | Part Name | ASTM Material | ||

|---|---|---|---|---|

| Carbon Steel | 1¼Cr-½Mo | Carbon Steel | ||

| 1 | Body | A216-WCB | A217-WC6 | A352-LCB |

| 2 | Bonnet Cap | A216-WCB | A217-WC6 | A352-LCB |

| 3 | Disc¹⁾ | A216-WCB+Cr13 | A217-WC6+HF | A352-LCB+CR13 |

| 4 | Hinge | A216-WCB | A217-WC6 | A352-LCB |

| 5 | Support | A216-WCB | A217-WC6 | A352-LCB |

| 6 | Seat Ring | A105+HF | A182-F11+HF | A350-LF2+HF |

| 7 | Hinge Pin | A276-420 | A276-304 | A276-420 |

| 8 | Disc Washer | Carbon Steel | A276-304 | Carbon Steel |

| 9 | Disc Nut | Carbon Steel | A194-7 | Carbon Steel |

| 10 | Disc Nut Pin | Carbon Steel | A276-420 | Carbon Steel |

| 11 | Bonnet Gasket | Steel Ring | 304SS Ring | Steel Ring |

| 12 | Bonnet Stud | A193-B7 | A193-B16 | A320-L7 |

| 13 | Bonnet Stud Nut | A194-2H | A194-7 | A194-4 |

| 14 | Eyebolt²⁾ | Carbon Steel | ||

| Note:1). Cast steel disc for NPS 4″and above. 2). NPS6″&larger. 3). Disc and seat ring may either be solid facing material or a base material equal to or better than the body/bonnet mate rial with facing as shown. |

||||

| NPS DN |

2 50 |

2½65 | 3 80 |

4 100 |

6 150 |

8 200 |

10 250 |

12 300 |

14 350 |

16 400 |

2 50 |

2½65 | 3 80 |

4 100 |

6 150 |

8 200 |

10 250 |

12 300 |

in mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

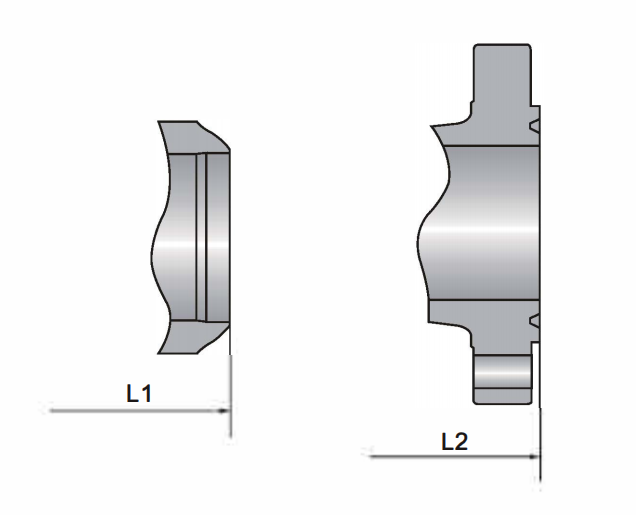

| ANSI Class 1500Lb | ANSI Class 2500Lb | ||||||||||||||||||

| L/L1 (RF/BW) |

14.50 368 |

16.50 419 |

18.50 470 |

21.50 546 |

27.75 705 |

32.75 832 |

39.00 991 |

44.50 1130 |

49.50 1257 |

54.50 1384 |

17.75 451 |

20.00 508 |

22.75 578 |

26.50 673 |

36.00 914 |

40.25 1022 |

50.00 1270 |

56.00 1422 |

in mm |

| L2 (RTJ) |

14.62 371 |

16.62 422 |

18.62 473 |

21.62 549 |

28.00 711 |

33.12 841 |

39.38 1000 |

45.12 1146 |

50.25 1276 |

55.38 1407 |

17.88 454 |

20.25 514 |

23.00 584 |

26.88 683 |

36.50 927 |

40.88 1038 |

50.88 1292 |

56.88 1445 |

in mm |

| H | 9.50 240 |

10.00 256 |

13.00 330 |

14.75 375 |

18.88 480 |

23.50 595 |

26.00 660 |

29.12 740 |

30.88 785 |

32.88 835 |

10.75 275 |

13.25 335 |

13.75 350 |

15.1 2385 |

19.50 495 |

24.62 625 |

28.00 712 |

35.6 2905 |

in mm |

| (d) | 47 | 57 | 69 | 92 | 136 | 177 | 222 | 263 | 288 | 330 | 38 | 47 | 57 | 72 | 111 | 146 | 184 | 218 | mm |

| WT (kg) |

40 29 |

63 47 |

70 49 |

115 84 |

250 152 |

470 310 |

740 470 |

1100 710 |

1410 910 |

1600 1100 |

50 35 |

76 55 |

85 68 |

165 115 |

460 225 |

900 580 |

1300 860 |

1800 1150 |

RF BW |