ANSI Cast Steel Gate Valve

150LB~2500LB

2″~48″ (50~1200mm)

Carbon Steel, Stainless Steel

ANSI Cast Steel Gate Valve Descriptions

ANSI cast steel gate valve is one type of valve whose on-off disc is the flexible wedge gate, whose moving direction is perpendicular with flow. Gate valve can be only full open or full close with full bore. ANSI gate valves are widely used in series of industries, especially in oil & gas filed, power plant, etc. Flowspec Luokai can produce the ANSI cast steel gate valve in accordance with ASME B16.34 and API600 with class rating of 150LB, 300LB, 600LB, 900LB, 1500LB and 2500LB. Just feel free to contact us now to get best prices. 30 years of experience. High quality. Big stock. Fast delivery.

1. FEATURES

- Full bore design

- OS&Y, outside screw and yoke

- Rising stem and non-rising hand wheel

- BB, bolted bonnet

- Flexible wedge (2″ Solid) , fully guided

- Choice of solid or split wedge

- Renewable seat rings

- Forged T-head stem

- By pass on request

- Available with gear operator

3. STANDARDS

- Design & manufacturing: ASME B16.34 / API600

- Face to face: ANSI B16.10

- Flanged ends: ANSI B16.5/B16.47

- Inspection & testing: API598

2. TECHNICAL SPECIFICATIONS

- 150LB~2500LB

- Size: 2″~48″ (DN50~1200mm)

- Materials: A216 WCB, S.S.304 CF8, S.S.316 CF8M

- Applicable medium: water, waste water, oil, gas, slurry, pulp

- Applicable temperature: -29℃~+425℃ (higher temperature is available upon request)

4. APPLICATIONS

- Mining, steel industry

- Coal, slurry industry

- Paper making industry

- Power plant

- Oil, chemical industry

- Fertilizer, pharmaceutical industry

- Waste water, sludge, sewage treatment industry

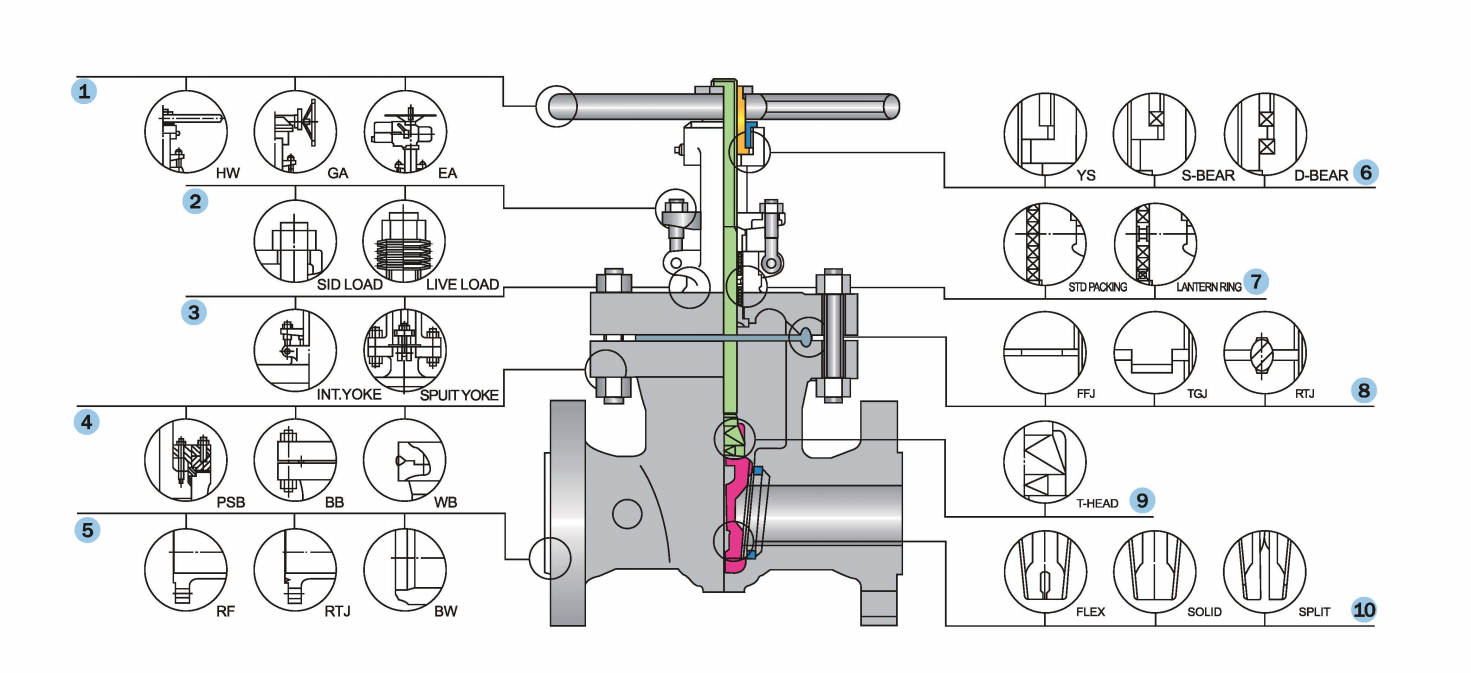

1 Operating

Large hand wheels for easyoperation. Also available withgearing, motor actuators,pneumatic or hydraulicactuators for more difficultservices.

2 Live Load Packing

In services requiring frequentcycling or with high pressure/temperature variations, liveloading extends the servicelife between maintenanceperiods by requiring lessfrequent packing gland adju-stments. Belleville springs areemployed to provide constantpacking gland stress.

3 OS &Y

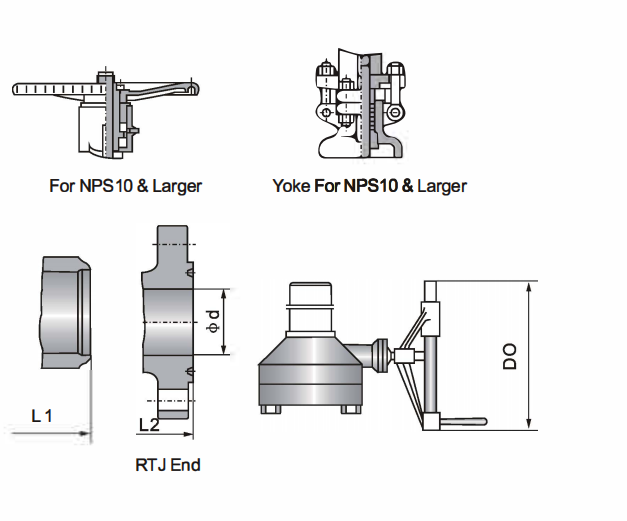

Outside Screw and Yoke.Cast steel gate valve yoke.Integral with bonnet for150ILb-8”,300Lb-8”,600Lb-6”, 900Lb-4”&Small.

4 BB

Bolted bonnet. Weldingbonnet and pressure sealbonnet in services requiringfrequent cycling or withhigh pressure/ temperaturevariations.

5 End Connections

A choice of Flanged, RTJflanged or Butt welding endfor piping flexibility

6 Yoke Sleeve

Extra long threadengagement between yokesleeve and stem providelong thread life. Valves ofsizes larger than 150Lb-12″,300Lb-10″,600Lb-6″,900Lb/1500Lb/2500Lb-4″are regularly provided withroll bearing yokes.

7 Lantern Ring andDouble Packing set

Lantern ring with leak-off fittingconnection and double packingstack is optionally available forcritical services.

8 Body-to-Bonnet Joint

A flat face gasket joint isused in the 150Lb valves.A male and female joint isused in 300Lb to 600Lbvalves. Ring joint is used inthe body to bonnetconnection in 900Lb&higher rated valves.

9 Stem

All wedge gate valves are providedwith upset forged T-headstems. By forging the T-head,the stem at the stem-wedgeconnection is stregthended. Thisdesign also allows the wedgeto self-align, eliminating thepossibility of a bent stem jammingthe wedge.

10 Wedge

Integral guide rib faces assureself-centering of wedge. Flexiblewedge gate valve has a one-piece, twin-disc wedge, which isdesigned so that each half flexesindependently. Available insolid, flex split and HIS designs.

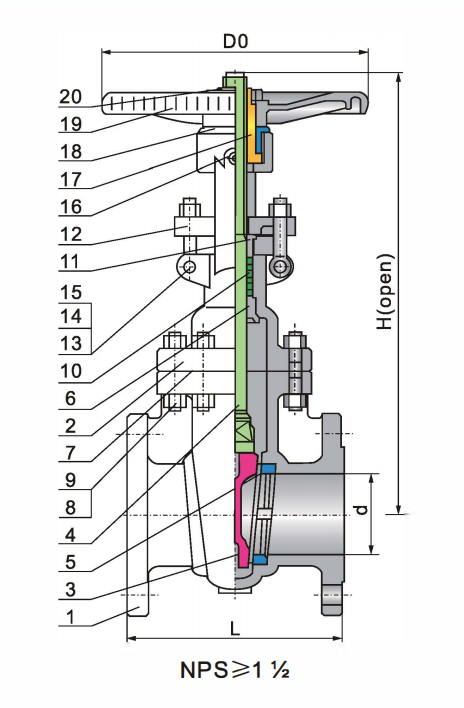

| No | Part Name | ASTM Material | ||

|---|---|---|---|---|

| Carbon Steel | 1¼Cr-½Mo | Carbon Steel | ||

| 1 | Body | A216-WCB | A217-WC6 | A352-LCB |

| 2 | Bonnet | A216-WCB | A217-WC6 | A352-LCB |

| 3 | Wedge | A216-WCB+CR13 | A217-WC6+HF | A352-LCB+CR13 |

| 4 | Stem | A182-F6a | CR-MO-V | A182-F6a |

| 5 | Seat Ring | A105+CR13 | A182-F11+HF | A350-LF2+CR13 |

| 6 | Stem Back Seat | A276-420 | A276-304 | A276-420 |

| 7 | Bonnet Gasket | Spiral Wound(Graphite+304) | ||

| 8 | Bonnet Stud | A193-B7 | A193-B16 | A320-L7 |

| 9 | Bonnet Stud Nut | A194-2H | A194-7 | A194-4 |

| 10 | Packing | Graphite | ||

| 11 | Gland | A276-420 | A276-304 | A276-420 |

| 12 | Gland Flange | A216-WCB | A217-WC6 | A352-LCB |

| 13 | Eyebolt Pin | Carbon Steel | A276-420 | Carbon Steel |

| 14 | Eyebolt | Carbon Steel | A193-B7 | Carbon Steel |

| 15 | Eyebolt Nut | Carbon Steel | A194-2H | Carbon Steel |

| 16 | Grease Fitting | Brass+Steel | ||

| 17 | Yokesleeve | Aluminum-Bronze¹⁾ | ||

| 18 | Yokesleeve Jam Nut | Carbon Steel | ||

| 19 | Handwheel | Malleable Iron | ||

| 20 | Handwheel Nut | Carbon Steel | ||

| Note:1). Ductile Ni-Resist optionalRTJ End 2). Wedge and seat ring may either be solid facing material or a base material equal to or better than the body/bonnet material with facing as shown. |

||||

| NPS DN |

2 50 |

2½65 | 3 80 |

4 100 |

6 150 |

8 200 |

10 250 |

12 300 |

14 350 |

16 400 |

18 450 |

20 500 |

24 600 |

26 650 |

28 700 |

30 750 |

32 800 |

36 900 |

40 1000 |

42 1050 |

48 1200 |

in mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANSI Class 150Lb | ||||||||||||||||||||||

| L (RF) |

7.00 178 |

7.50 191 |

8.00 203 |

9.00 229 |

10.50 267 |

11.50 292 |

13.00 330 |

14.00 356 |

15.00 381 |

16.00 406 |

17.00 432 |

18.00 457 |

20.00 508 |

22.00 559 |

24.00 610 |

24.00 610 |

28.00 711 |

28.00 711 |

32.00 813 |

32.00 813 |

42.00 1067 |

in mm |

| L1 (BW) |

8.5 216 |

9.50 241 |

11.12 283 |

12.00 305 |

15.88 403 |

16.50 419 |

18.00 457 |

19.75 502 |

22.50 572 |

24.00 610 |

26.00 660 |

28.00 711 |

32.00 813 |

34.00 864 |

36.00 914 |

36.00 914 |

38.00 965 |

40.00 1016 |

42.00 1067 |

45.00 1143 |

53.97 1371 |

in mm |

| L1 (RTJ) |

7.48 190 |

7.99 203 |

8.50 216 |

9.48 241 |

10.98 279 |

12.00 305 |

13.50 343 |

14.48 368 |

15.51 394 |

16.49 419 |

17.51 445 |

18.50 470 |

20.51 521 |

‐‐ | ‐‐ | 24.48 622 |

‐‐ | 28.50 724 |

‐‐ | ‐‐ | ‐‐ | in mm |

| H (OPEN) |

15.25 386 |

17.00 434 |

18.88 480 |

23.00 584 |

30.50 765 |

37.62 956 |

45.50 1149 |

53.12 1350 |

59.38 1508 |

67.00 1703 |

74.50 1892 |

83.50 2119 |

98.25 2500 |

110.50 2806 |

116.50 2960 |

124.00 3150 |

129.00 3280 |

146.50 3720 |

130.00 3302 |

136.96 3479 |

161.70 3962 |

in mm |

| (d) | 50 | 63 | 76 | 100 | 150 | 200 | 250 | 300 | 336 | 387 | 438 | 488 | 590 | 641 | 692 | 743 | 781 | 876 | ‐ | ‐ | – | mm |

| D0 | 8 200 |

8 200 |

10 250 |

12 300 |

12 300 |

14 350 |

16 400 |

18 450 |

20 500 |

22 550 |

24 600 |

26 640 |

29 720 |

29 720 |

32 800 |

32 800 |

38 950 |

40 1000 |

40.15 1020 |

40.15 1020 |

40.15 1020 |

in mm |

| WT (kg) |

18 15 |

25 18 |

32 26 |

50 41 |

77 69 |

121 108 |

178 156 |

265 248 |

363 330 |

463 424 |

621 587 |

792 752 |

1190 1144 |

1521 1570 |

1838 1900 |

2261 3310 |

2490 2540 |

3310 3380 |

4650 – |

5100 – |

6500 – |

RF BW |

| Toqure | 13 | 13 | 15 | 27 | 36 | 63 | 84 | 131 | 151 | 235 | 285 | 341 | 602 | ‐ | ‐ | 1079 | ‐ | 1497 | – | ‐ | ‐ | mm |