ANSI Cast Steel Globe Valve Descriptions

ANSI cast steel globe valve is also called stop valve, which is one type of the most important shut-off valves. Globe valve is open or close by bringing pressure to the valve stem, and the stem bring pressure to the valve disc, achieving the sealing surface to be without leakage by force. There are straight type globe valve, angle type globe valve and plunger type globe valve. And globe valves can be with flanged ends, threaded ends and welded ends. ANSI globe valves are widely used in series of industries, especially in oil & gas filed, power plant, etc. Just feel free to contact us now to get best prices. 30 years of experience. High quality. Big stock. Fast delivery.

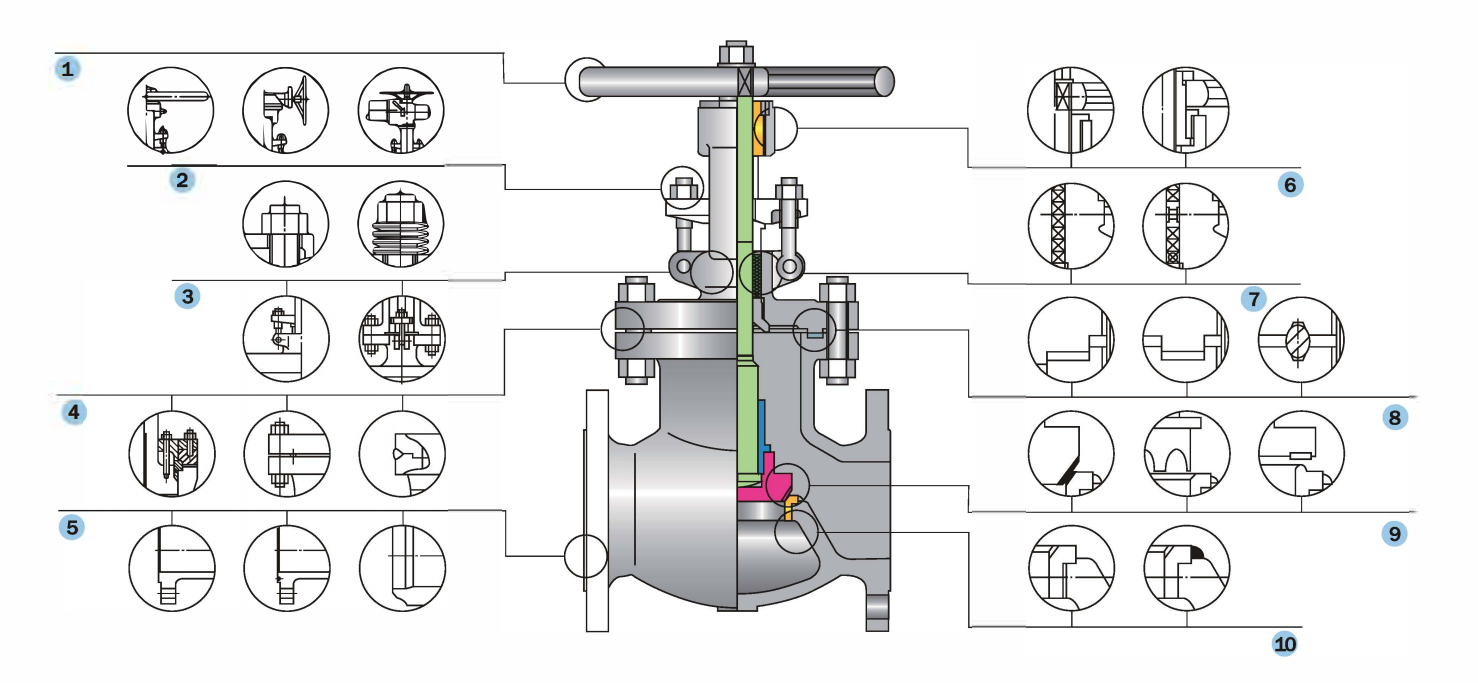

1. FEATURES

- Straight pattern body design

- OS&Y, outside screw and yoke

- BB, bolted bonnet

- Yoke integral with bonnet

- Rising stem and hand wheel

- Loose disc, choice of plug or ball

- Renewable seat ring

- Impact hand wheel for 10” & above

- Horizontal service

- Flanged or butt-welding ends

- Available with gear box operator

3. STANDARDS

- Design & manufacturing: ASME B16.34/BS 1873

- Face to face: ASME B16.10

- Flanged ends: ASME B16.5/B16.47

- Inspection & testing: API598

2. TECHNICAL SPECIFICATIONS

- 150LB~2500LB

- Size: 2″~18″ (DN50~450mm)

- Materials: carbon steel, cast steel, A216 WCB

- Applicable medium: water, oil, gas

- Applicable temperature: -29℃~+425℃

- Special: NACE MR-01-75

4. APPLICATIONS

- Petroleum

- Chemical Industry

- Pharmacy

- Chemical Fertilizer

- Power Plant

- Textile

- Printing & Dyeing

- Oil & Gas

Large handwheels for

easy operation. Also

available with gearing.

motor actuators,

pneumatic or hydraulic

actuators for

more difficult services.

2 LIVE Load Packing

In services requiring

frequent cycling or with high

pressure/temperature

variations, live loading

estends the service life

between maintenance periods

by requiring less frequent

packing gland adjustments.

Belleville springs are

employed to privide constant

packing gland stress.

3 OS & Y

Outside Screw and Yoke.

Cast steel gl obe valve yoke

integral with bonnet for 10&

and smaller.

4 BB

Bolted bonnet. Welding

bonnet and pressure

seal bonnet inservices

requiring frequent cycling

or with high pressure/

temperature variations.

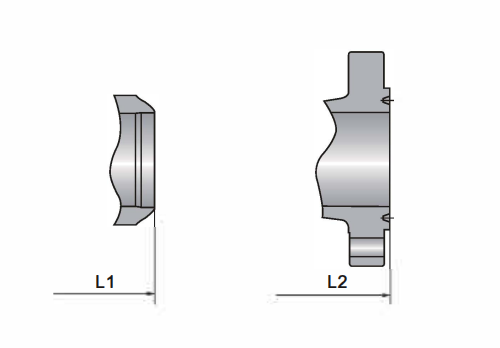

5 End Connections

End Connections

A choice of Flanged,

RFJ flanged of Buttwelding

end for piping flexibility.

6 Yokesleeve

Fumished in aluminum

bronze to reduce

operating torque, Most

sizes fumished with ball

bearing yokesleeves.

7 Lantern ring and

double packing set

Lantem ring with leak-off

fitting connection and double

packing stack is optionally

available for critical services.

8 Body-to-Bonnet Joint

A Male and Female joint

or Tongue and Groove

joint is used 150Lb to

600Lb valves. Ring joint is

used in the body to bonnet

connection in900Lb&

higher rated valves.

9Disc

Plug disc is stom guided on allsizes. Disc has a differential angle

front the seat to provide a line

contact for maximum sealing.

The bottom of V-port disc is

fuided by the body seat

ring for maximum disc stability

in throttling applications. The

soft TEFL ON ring is excellent

for lower temperature service

where tight shutoff is required.

10 Seat Rings

Separate heavy duty, full

ported rings for easy

maintenance. Screwed or

welded connection into

body.

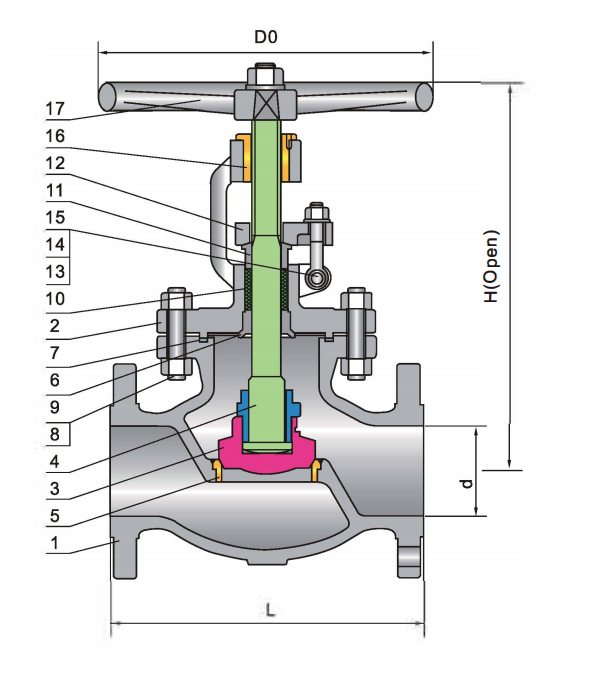

| No | Part Name | ASTM Material | ||

|---|---|---|---|---|

| Carbon Steel | 1¼Cr-½Mo | Carbon Steel | ||

| 1 | Body | A216-WCB | A217-WC6 | A352-LCB |

| 2 | Bonnet | A216-WCB | A217-WC6 | A352-LCB |

| 3 | Disc | A105+CR13 | A182-F11+HF | A3510-LF2+CR13 |

| 4 | Stem | A182-F6a | CR-MO-V | A182-F6a |

| 5 | Seat Ring | A105+CR13 | A182-F11+HF | A350-LF2+CR13 |

| 6 | Stem BackSeat | A276-420 | A276-304 | A276-420 |

| 7 | Bonnet Gasket | Spiral Wound(Graphite+304) | ||

| 8 | Bonnet Stud | A193-B7 | A193-B16 | A320-L7 |

| 9 | Bonnet Stud Nut | A194-2H | A194-7 | A194-4 |

| 10 | Packing | Graphite | ||

| 11 | Gland | A276-420 | A276-304 | A276-420 |

| 12 | Gland Flange | A216-WCB | A217-WC6 | A352-LCB |

| 13 | Eyebolt Pin | Carbon Steel | A276-420 | Carbon Steel |

| 14 | Eyebolt | Carbon Steel | A193-B7 | Carbon Steel |

| 15 | Eyebolt Nut | Carbon Steel | A194-2H | Carbon Steel |

| 16 | Yokesleeve | Aluminum-Bronze¹⁾ | ||

| 17 | Handwheel | Malleable Iron | ||

| Note:1). Ductile Ni-Resist optional 2). Disc and seat ring may either be solid facing material or a base material equal to or better than the body/bonnet material with fading as shown. |

||||

| NPS DN |

2 50 |

2½65 | 3 80 |

4 100 |

6 150 |

8 200 |

10 250 |

12 300 |

14 350 |

16 400 |

18 450 |

20 500 |

24 600 |

in mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ANSI Class 150Lb | ||||||||||||||

| L/L1 (RF/BW) |

8.00 203 |

8.50 216 |

9.50 241 |

11.50 292 |

16.00 406 |

19.50 495 |

24.50 622 |

27.50 698 |

31.00 787 |

36.00 914 |

38.46 977 |

38.46 977 |

50.98 1295 |

in mm |

| L2 (RTJ) |

8.00 203 |

8.50 216 |

9.50 241 |

11.50 292 |

16.00 406 |

19.50 495 |

24.50 622 |

27.50 698 |

31.00 787 |

36.00 914 |

‐‐ | ‐‐ | ‐‐ | in mm |

| H (OPEN) |

15.00 380 |

21.00 535 |

17.50 445 |

20.25 515 |

22.00 560 |

24.25 615 |

32.00 815 |

35.88 910 |

48.38 1230 |

57.00 1450 |

41.96 1066 |

43.97 1117 |

50.98 1295 |

in mm |

| (d) | 50 | 63 | 76 | 100 | 150 | 200 | 250 | 300 | 360 | 387 | 438 | 488 | 590 | mm |

| D0 | 7 180 |

10 240 |

11 280 |

11 280 |

13 320 |

13 320 |

16 400 |

18 450 |

20 500 |

24 600 |

28.34 720 |

28.34 720 |

33.46 850 |

in mm |

| WT (kg) |

18 14 |

30 22 |

41 33 |

64 43 |

86 72 |

110 88 |

280 245 |

380 345 |

510 450 |

740 665 |

1150 – |

1650 – |

2200 – |

RF BW |

| ANSI Class 300Lb | ||||||||||||||

| L/L1 (RF/BW) |

10.50 267 |

11.50 292 |

12.50 318 |

14.00 356 |

17.50 444 |

22.00 559 |

24.50 622 |

28.00 711 |

32.99 838 |

32.99 863 |

38.46 977 |

40.00 1016 |

52.99 1346 |

in mm |

| L2 (RTJ) |

11.12 282 |

12.12 308 |

13.12 333 |

14.62 371 |

18.12 460 |

22.62 575 |

25.12 638 |

28.62 727 |

‐‐ | ‐‐ | ‐‐ | ‐‐ | ‐‐ | in mm |

| H (OPEN) |

16.75 425 |

19.00 485 |

19.88 505 |

22.50 570 |

25.25 640 |

33.25 845 |

35.50 900 |

38.62 980 |

‐‐ | 53.97 1371 |

57.99 1473 |

61.96 1574 |

70.98 1803 |

in mm |

| (d) | 50 | 63 | 76 | 100 | 150 | 200 | 250 | 300 | 336 | 387 | 431 | 482 | 584 | mm |

| D0 | 8 200 |

10 240 |

11 280 |

13 320 |

16 400 |

18 450 |

20 500 |

24 600 |

33.85 860 |

24.0 1610 |

24.0 1610 |

28.34 720 |

28.34 720 |

in mm |

| WT (kg) |

25 20 |

32 22 |

38 27 |

56 41 |

96 75 |

150 117 |

360 310 |

550 492 |

876 ‐ |

1200 ‐ |

1600 ‐ |

2100 ‐ |

3150 ‐ |

RF BW |