Product information

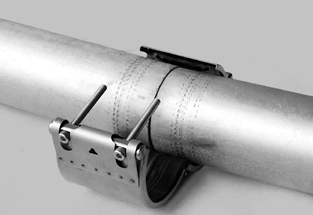

LCH folding type pipe repair clamp is one type of device that is used to repair the pipe breaks, impact damage, holes, longitudinal and corrosion, which features with flexible connection, strong & anti-corrosive, no need welding, no fire risk, space saving, suitable for any pipe, easy installation. The pipe repair clamp is widely applicable to many types of pipelines, such like gas pipeline, water pipes, oil pipes, compressed air pipes, pvc pipes, and in series of fields of water supply, gas supply, ship building, offshore oil platform and water treatment. Flowspec Luokai can manufacture the LCH folding type pipe repair clamp according to DIN86128-1/2, AWWA standard.

1. FEATURES

- Flexible connection

- Strong & anti-corrosive

- No need welding, no fire risk

- Space saving, easy installation

- Suitable for any pipe

3. STANDARDS

- Complies with DIN86128-1/2, AWWA (other sizes available upon request)

2. TECHNICAL SPECIFICATIONS

- Working pressure: 6~32bar

- Size: 15A-2000A (other sizes available upon request)

- Materials: AISI304, AISI316, AISI316, AISI316L, AISI3220S

- Pressure testing: 1.5 x PB

4. APPLICATIONS

- Applicable pipe: crude oil pipeline, gas pipeline, natural gas pipeline, water supply & drainage pipeline, fuel oil pipeline, airline pipeline, automobile pipeline, lubricating oil pipeline, sludge pipeline, suction pipeline, water power pipeline, sea water pipeline, fresh water pipeline, turbine pipeline, air conditioning pipeline, fire fighting pipeline, ventilation pipeline, compressed air pipeline

- Applicable field: surface pipe, underground engineering, ship building, offshore oil platform, water supply, coal gas supply, natural gas supply, power, industries, sewage treatment & maintenance

- Applicable temperature: -20℃~+120℃

SPECIFICATIONS

• Features: flexible connection, strong & anti-corrosive, no need welding, no fire risk, space saving, suitable for any pipe, easy installation.

• Application field: surface pipe, underground engineering, ship building, offshore oil platform, water supply, coal gas supply, natural gas supply, power, industries, sewage treatment & maintenance.

• Application pipeline: crude oil pipeline, gas pipeline, natural gas pipeline, water supply & drainage pipeline, fuel oil pipeline, airline pipeline, automobile pipeline, lubricating oil pipeline, sludge pipeline, suction pipeline, water power pipeline, sea water pipeline, fresh water pipeline, turbine pipeline, air conditioning pipeline, firefighting pipeline, ventilation pipeline, compressed air pipeline.

• Versatility: Apply to any pipe, to connect different materials of different axial, different diameter pipe, for quick repairs.

• Economy: The first pipe needn’t deal with, can be connected, thin-walled, thick-walled tube, the installation is simple, a significant reduction in construction costs.

• Reliability: It can compensate the axial displacement and the angle crab, the apron lip-like structure can be increased with the pressure enhanced sealing effect.

FAST INSTALLATION

• Light weight

• Few bolts

• Low torque requirement

ACCOMMODATES

• Angular deflection

• Pipes with gaps between pipe ends

• Connection of pipe with movement

• Cracked pipe

COMPATIBLE PIPE MATERIALS

• Steel

• Cast iron / Ductile Iron

• Asbestos Cement

• Concrete

• PVC

• HDPE

MATERIALS

• Shell: 304 Stainless steel (other materials available upon request)

Sidebars: 304 Stainless steel (other materials available upon request)

• Bolts: 304 Stainless steel (other materials available upon request)

Gasket Bridge: 304 Stainless steel (other materials available upon request)

• Gasket: •EPDM (-20~+130℃ water, air, dust, steam)

• NBR (-20~+100℃ natural gas, coal gas, oil, other hydrocarbon)

• SILICON (-75~+200℃ anti-exposure, coal gas, oil, other hydrocarbon)

• VITON (-95~+300℃ anti-heat, anti-corrosive)

SIZE RANGE

• 15A-2000A (other sizes available upon request)

STANDARD

• Complies with DIN86128-1/2, AWWA (other sizes available upon request)

PRESSURE TESTING

• 1.5 x PB

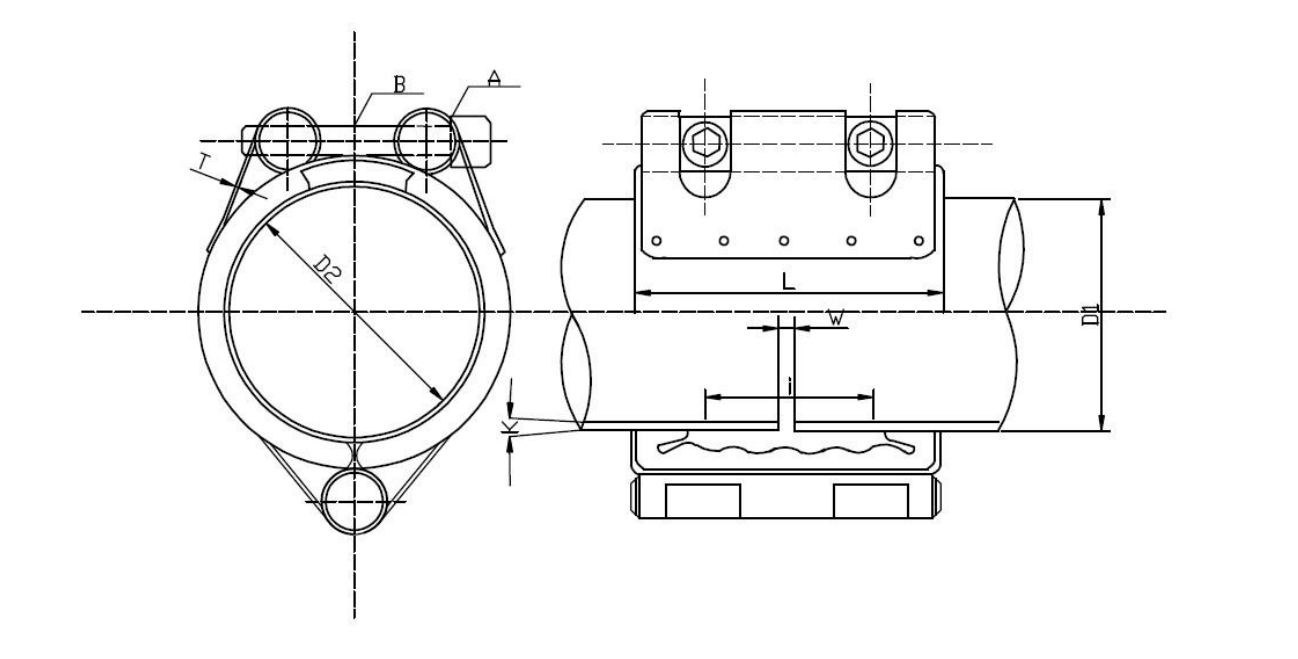

| MODEL | D1 | D2 | ΦB | ΦA | L | I | T | W.P. | PRE-TIGHTENING FORCE |

|---|---|---|---|---|---|---|---|---|---|

| (MM) | (MM) | (MM) | (MM) | (MM) | (MM) | (MM) | (BAR) | (BAR) | |

| LCH-S 15A | 21.7 | 21-23 | M6 × 45L × 2 | 10 | 57 | 33 | 0.8 | 18 | 30-60 |

| LCH-S 20A | 27 | 26-28 | M6 × 45L × 2 | 10 | 57 | 33 | 0.8 | 18 | 30-60 |

| LCH-S 25A | 34 | 33-35 | M6 × 45L × 2 | 10 | 57 | 33 | 0.8 | 18 | 30-60 |

| LCH-S 32A | 42.7 | 42-44 | M8 × 55L × 2 | 12 | 57 | 33 | 0.8 | 18 | 50-80 |

| LCH-S 40A | 48.6 | 47-49 | M8 × 55L × 2 | 12 | 57 | 33 | 0.8 | 18 | 50-80 |

| LCH-S 50A | 60.5 | 58-61 | M10 × 75L × 2 | 16 | 80 | 46 | 1 | 16 | 80-100 |

| LCH-S 65A | 76.3 | 75-78 | M10 × 75L × 2 | 16 | 80 | 46 | 1 | 16 | 80-100 |

| LCH-S 80A | 89.1 | 88-92 | M12 × 90L × 2 | 18 | 107 | 65 | 1.2 | 14 | 120-150 |

| LCH-S 100A | 114.3 | 113-117 | M12 × 90L × 2 | 18 | 107 | 65 | 1.2 | 14 | 120-150 |

| LCH-S 125A | 139.8 | 138-142 | M14 × 110L × 2 | 22 | 116 | 71 | 1.5 | 12 | 180-250 |

| LCH-S 150A | 165.2 | 163-167 | M14 × 110L × 2 | 22 | 116 | 71 | 1.5 | 12 | 180-250 |

| LCH-S 200A | 216.3 | 214-219 | M16 × 130L × 2 | 28 | 155 | 80 | 2 | 10 | 250-400 |

| LCH-S 250A | 267.3 | 265-270 | M16 × 130L × 2 | 28 | 155 | 80 | 2 | 10 | 250-400 |

| LCH-S 300A | 318.5 | 316-321 | M16 × 140L × 2 | 28 | 155 | 80 | 2 | 8 | 500-800 |

| LCH-S 350A | 355.6 | 353-358 | M16 × 140L × 2 | 28 | 155 | 80 | 2 | 8 | 500-800 |

| LCH-S 400A | 406.4 | 403-408 | M18 × 150L × 2 | 30 | 155 | 80 | 2 | 6 | 800-1000 |

| LCH-S 450A | 457.2 | 455-461 | M18 × 150L × 2 | 30 | 155 | 80 | 2 | 6 | 800-1000 |

| LCH-S 500A | 508 | 505-512 | M18 × 150L × 2 | 30 | 155 | 80 | 2 | 6 | 1000-1200 |

| MODEL | D1 | D2 | ΦB | ΦA | L | I | T | W.P. | PRE-TIGHTENING FORCE |

|---|---|---|---|---|---|---|---|---|---|

| (MM) | (MM) | (MM) | (MM) | (MM) | (MM) | (MM) | (BAR) | (BAR) | |

| LCH-L 15A | 21.7 | 21-23 | M8 × 45L × 3 | 12 | 100 | 70 | 0.8 | 18 | 30-60 |

| LCH-L 20A | 27.0 | 26-28 | M8 × 45L × 3 | 12 | 100 | 70 | 0.8 | 18 | 30-60 |

| LCH-L 25A | 34.0 | 33-35 | M8 × 45L × 3 | 12 | 100 | 70 | 0.8 | 18 | 30-60 |

| LCH-L 32A | 42.7 | 42-44 | M8 × 55L × 3 | 12 | 100 | 70 | 0.8 | 18 | 50-80 |

| LCH-L 40A | 48.6 | 47-49 | M8 × 55L × 3 | 12 | 100 | 70 | 0.8 | 18 | 50-80 |

| LCH-L 50A | 60.5 | 58-61 | M10 × 75L × 3 | 16 | 139 | 46 | 1.0 | 16 | 80-100 |

| LCH-L 65A | 76.3 | 75-78 | M10 × 75L × 3 | 16 | 139 | 46 | 1.0 | 16 | 80-100 |

| LCH-L 80A | 89.1 | 88-92 | M12 × 90L × 32 | 18 | 203 | 65 | 1.2 | 14 | 120-150 |

| LCH-L 100A | 114.3 | 113-117 | M12 × 90L × 3 | 18 | 203 | 65 | 1.2 | 14 | 120-150 |

| LCH-L 125A | 139.8 | 138-142 | M14 × 110L × 3 | 22 | 204 | 71 | 1.5 | 12 | 180-250 |

| LCH-L 150A | 165.2 | 163-167 | M14 × 110L × 3 | 22 | 204 | 71 | 1.5 | 12 | 180-250 |

| LCH-L 200A | 216.3 | 214-219 | M16 × 130L × 3 | 28 | 255 | 80 | 2.0 | 10 | 250-400 |

| LCH-L 250A | 267.3 | 265-270 | M16 × 130L × 3 | 28 | 255 | 80 | 2.0 | 10 | 250-400 |

| LCH-L 300A | 318.5 | 316-321 | M16 × 140L × 3 | 28 | 255 | 80 | 2.0 | 8 | 500-800 |

| LCH-L 350A | 355.6 | 353-358 | M16 × 140L × 3 | 28 | 255 | 80 | 2.0 | 8 | 500-800 |

| LCH-L 400A | 406.4 | 403-408 | M18 × 150L × 3 | 30 | 255 | 80 | 2.0 | 6 | 800-1000 |

| LCH-L 450A | 457.2 | 455-461 | M18 × 150L × 3 | 30 | 255 | 80 | 2.0 | 6 | 800-1000 |

| LCH-L 500A | 508.0 | 505-512 | M18 × 150L × 3 | 30 | 255 | 80 | 2.0 | 6 | 1000-1200 |